Industry machine parts metal CNC | Инструменты

Сохраните в закладки:

История цены

*История изменения цены! Указанная стоимость возможно, уже изменилось. Проверить текущую цену - >

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-17-2025 | 0.27 руб. | 0.37 руб. | 0 руб. |

| Aug-17-2025 | 0.31 руб. | 0.46 руб. | 0 руб. |

| Jul-17-2025 | 0.34 руб. | 0.26 руб. | 0 руб. |

| Jun-17-2025 | 0.30 руб. | 0.26 руб. | 0 руб. |

| May-17-2025 | 0.88 руб. | 0.6 руб. | 0 руб. |

| Apr-17-2025 | 0.77 руб. | 0.50 руб. | 0 руб. |

| Mar-17-2025 | 0.19 руб. | 0.7 руб. | 0 руб. |

| Feb-17-2025 | 0.41 руб. | 0.66 руб. | 0 руб. |

| Jan-17-2025 | 0.32 руб. | 0.57 руб. | 0 руб. |

Новые товары

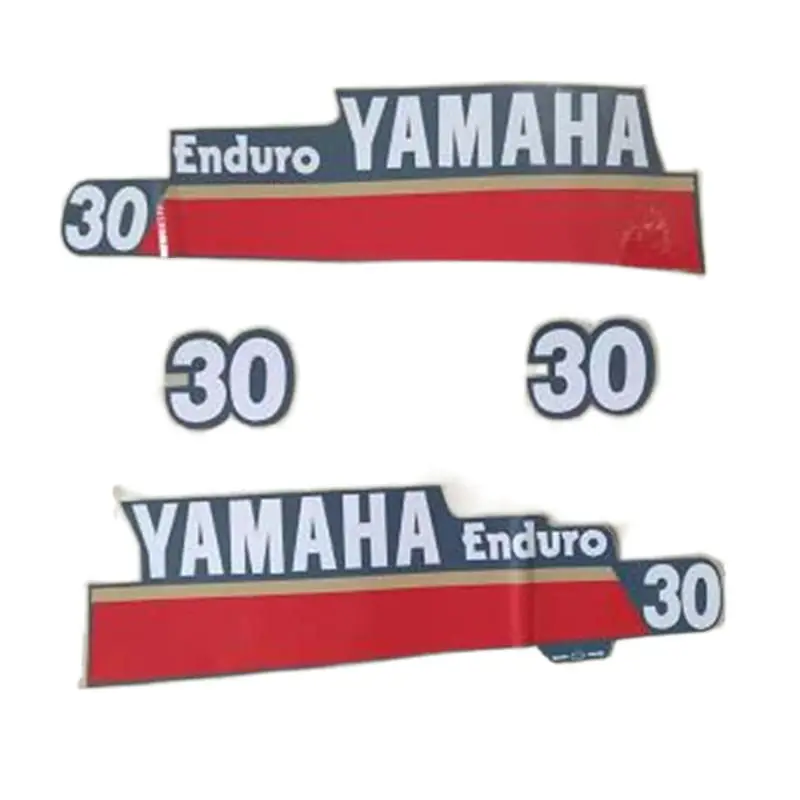

КОМПЛЕКТ НАКЛЕЕК E30 E40 E60 2 ТАКТ 30 л.с. 40 л.с. 60 л.с. ENDURO OUTBOARDS ДВИГАТЕЛЬ ДЛЯ МОТОРНОГО КАТЕРА МОРСКАЯ ДЕКОРАЦИЯ.

Лента Тканевая Обтекательная Катушка с Креплением Зажимом для Обметывания Машины Шитья Аксессуары.

Экскаватор Komatsu 130/200/220/300/360-7, блок внешней ручки замка двери кабины и внутренний.

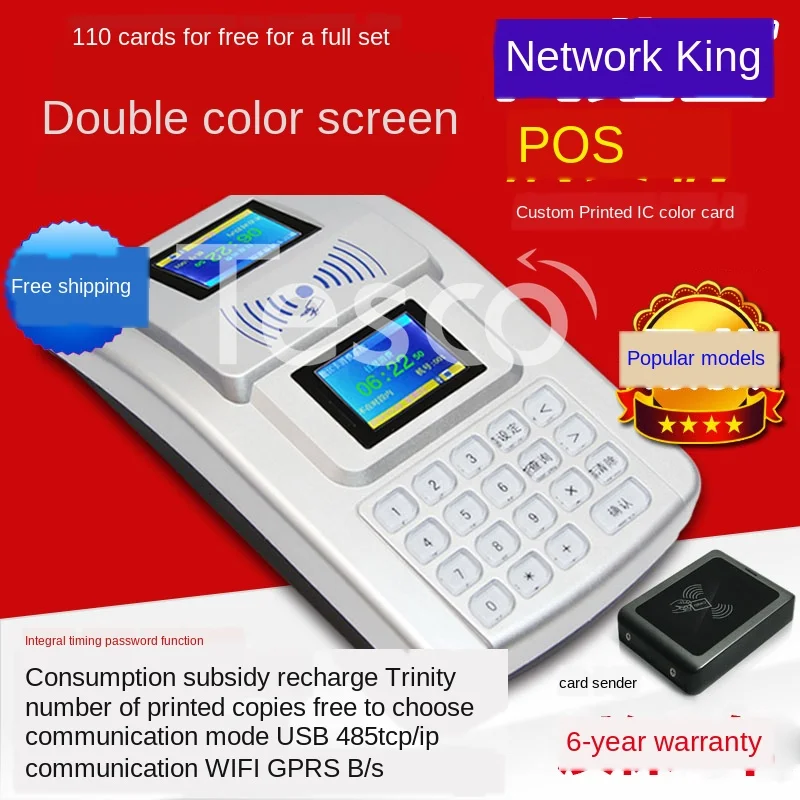

Автомат для оплаты кредитной картой в столовой Sony Canteen, подключенный к сети автоматических торговых аппаратов для приема питания.

Многофункциональная Оловянная стальная сетка для растений материнской платы

Универсальный набор для снятия и установки распределительной цепи мотоцикла для ATV, квадроцикла, грязевого и мотоцикла мотокросса и мотарда.

10 шт. большие петли для распределительного шкафа | Детали инструментов AliExpress

Защита при торговле мотором Poclain MS05 MS18 MS25 MS35 MS50 MS83, серия MS18-1-111, MS11-2-121-F11-1120-000 Гидравлический поршень.

Характеристики

Industry machine parts metal CNC | Инструменты

Описание товара

2.Steel:C45(K1045), C46(K1046),C20

3.Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200CuZn37), C28000(CuZn40)

4.Bronze: C51000, C52100, C54400, or customized

5.Iron: 1213, 12L14,1215

6.Aluminum: Al6061, Al6063 , or customized

7.Carbon steel:C1006,C1010,C1018,C1022,C1035K,C1045,12L14

8. Alloy steel: SCM435,C10B21,C10B33 Finish Zn- Plated,Ni-plated,Passivated,Tin-plated,Sandblast and Anodize,Chromate, Polish,Electro Painting,Black Anodize,Plain,Chrome plated,Hot Deep Galvanize(H. D. G. ) Processing methods Aluminium profile extruding,Precise cutting,

Straight rectification,Bending,Drilling,Tapping,Stamping,Pulling,CNC mill, CNC lathe,CNC machining… Standard ISO,GB,DIN,JIS,ANSI,BSW Tolerance +/-0.01mm Color metal color are available Drawing required OEM/ODM welcomed Facility Full range of extrusion cutting maches,CNC turning machines, stamping machines, casting machines and CNC lathe machines etc Service we will follow up goods for every customer and help solve problem after sales. Inspection 100% QC steps inspect before shipment Warranty we confirm our goods will satisfy your request of 100%,and have 18 month warranty. Payment T/T,L/C,D/A,D/P,Western Union,MoneyGram etc Price terms FOB/CIF etc Delivery time 5-7 workdays for samples, 10-20 days for bulk order Packaging Detail Neutral carton, OEM customized box Certification ISO9001: 2008 with Standard or non-standard

Our factory overview:

Plastic injection mold:

Injection molding parts:

CNC Machining process for metal parts :

Auto-CNC lathe parts:

Die-casting mold:

Die-casting molding parts:

Stamping mold:

Stamping molding parts:

CNC machining process for plastic parts:

Stereolithography(SLA/SLS Printing process):

PCB Fabrication service:

Secoundary operation:

Final assembly service:

Quality control :

Our SLA Printing Machines :

Our SLS printing Machines:

Our CNC machine center workshop:

Our auto-CNC lathe work shop:

Plastic tooling/mold manufacturing workshop:

Our injection molding workshop:

Our metal stamping workshop:

PCB Assembly Process Overview:

The various stages in the PCB assembly process including adding solder paste to the board, pick and place of the components, soldering, inspection and test. All these processes are required, and need to be monitored to ensure that product of the highest quality is produced. The PCB assembly process described below assumes that surface mount components are being used as virtually all PCB assembly these days uses surface mount technology.

Our PCBA Workshop:

About us :

SMARTTECH are a mold and injection molding ,CNC Machining process,metal punching product,PCB fabrication and rapid prototyping manufacturing company, based in HongKong with branches in Shenzhen city and DongGuan city. Our company is market oriented, Now we buy many 3D printing machine for industy with a experienced and dedicated staff that focus on offering various high technologies processes.

SMARTTECH is a leader in the domestic business field and is also highly competitive within many international markets. Shenzhen company was founded in May, 2006. Meanwhile, we are further developing international sales branches in Shenzhen and DongGuan. The development team has increased not only the number of staff but also the significant skill base. These include professional quotation operators, designers, figure file operators, and also several sales representative's fluent in English, Japanese, French, etc, providing the most professional relative services for the clients all over the world. Many industrial design and rapid prototyping companies from South Korea, Japan, India,Canada, United States, United Kingdom, Norway, Czech, Slovakia, Australia, New Zealand have established long-term business relationships with SMARTTECH.

Also SMARTTECH are a professional one-stop R&D engineering service provider, not only we were formed by a group of people who owned many years of practical R&D and manufacturing experience, but also we have the resource of special equipments and instruments for prototype PCBA making , testing and analyzing, product mechanical-structure prototype and tooling service, this will be a great help for your R&D departments, and increase the speed and effectivity for your new product development. Our service includes Product R&D engineering service and added-value R&D engineering service.

We operation complies with ISO9001 quality system instruction and requirements since Oct, 2008. SMARTTECH design has invested in advanced technologies and highly skilled work force. With these assets, we can model out of a very wide variety of materials including many sorts of plastics such as ABS, MABS, PMMA, PVC, PC, POM, PP, PA, PPT, PE etc. Of course the same is true for as many metals including stainless steel, aluminum and copper.

These items below can be supported by our factory, if you have any requirements, you're welcomed to send the inquiries at any time.

1.Plastic mould and metal mold making,die casting mold

2.ID design and development

3.Prototype both metal and plastic

4.Low volume assembly and design review

5. Mass production for the injection molding

6. Mechanical design and ID design

7. Finsih product assembly etc.

For more informations, Please kindly:

Трекер стоимости

Отзывы покупателей

Новые отзывы о товарах

В любом деле люблю аккуратность. Данный органайзер позволил идеально устроить рабочее место, в подставке хорошо помещаются основные необходимые канцелярские принадлежности.... Читать отзыв полностью...

Наконец то я приобрела очки, о которых давно мечтала. Спасибо продавцу. Цена радует меня. Качество очень хорошее. На лето... Читать отзыв полностью...

Заказывали тут, для фотосессии с новорожденной дочей. Удобно одевать, максимально простое, и в то же время очень красивое! Юбочка нам... Читать отзыв полностью...

Постоянно пользуюсь часами, удобно, что для любого случая можно менять цвет ремешка. У меня уже целая коллекция таких. Чёрный и... Читать отзыв полностью...

Минималистический дизайн наряду с удобностью часов дают отличное сочетание, купил недавно, однако чёрный вариант советую больше белого. Ремень часов при... Читать отзыв полностью...

Здравствуйте! Я заказала себе сразу 2 льняных комбинезона, на следующее лето. Потому что как многие знают именно лён как... Читать отзыв полностью...

Платье просто супер! Я долго искала себе платье к Новому году, хотела что-нибудь необычное и яркое. И вот наконец-то я... Читать отзыв полностью...